Companies that want to stay ahead of the curb are adopting cutting-edge technologies to automate and improve their warehouse operations. While altering the way your warehouse team works can seem challenging, the benefits of warehouse digitalization far outweigh the initial drawbacks or implementation costs.

Digitalization is the process of leveraging new and emerging technologies to transform and optimize business operations. When it comes to warehouses, digitalization looks like adopting tools like IoT devices, artificial intelligence (AI) systems, and cloud computing to enhance productivity and efficiency.

This blog post will take a closer look at the key components of warehouse digitalization, its key benefits, success stories of companies who have undergone this process, and how speech AI like aiOla can help your team with reliable data and automation capability.

Key Components for Understanding Warehouse Digitalization

More warehouses than ever are going digital. In fact, 82% of warehouses made major technology purchases in the last two years alone. The process of going digital is giving warehouses the power to access and implement cutting-edge technology for unprecedented levels of operational efficiency. Below, we discuss some of the technologies that digitalization offers warehouses and look at how they can make teams more productive.

Automated Processes and Robotics

Warehouses commonly adopt robotics to integrate more automated processes into their workflows. With robotics, manual and repetitive tasks like picking, packing, and sorting can be automated, reducing human error and labor costs.

Internet of Things (IoT) Integration

IoT devices like sensors and monitors allow for real-time monitoring and data collection into important workflows, like inventory levels, supply chain management, equipment maintenance needs, and more. IoT devices can help warehouse teams ensure communication across all warehouse operations for higher efficiency.

Cloud-based Warehouse Management Systems (WMS)

Cloud-based WMS platforms allow teams to remain scalable and flexible. WMSs enable warehouses to better manage inventory, fulfill orders, and plan supply chain logistics from one unified platform, and if it’s in the cloud, data can be accessed in real time from multiple locations.

Data Analytics and Predictive Insights

Using data analytics algorithms that pull information from historical data and market trends, companies can gain insights and better forecast inventory, demand, and maintenance needs. This helps warehouses plan more strategically, make well-informed decisions, and reduce downtime.

4 Main Benefits of Warehouse Digitalization

Traditional operations have been reliable, but fallible when it comes to preventing human error and enhancing operations and the customer experience. With the increase in logistics transformation and digitalization, companies are able to reap the benefits that these new technologies bring to be able to achieve gains in productivity, efficiency, safety, compliance, and customer satisfaction.

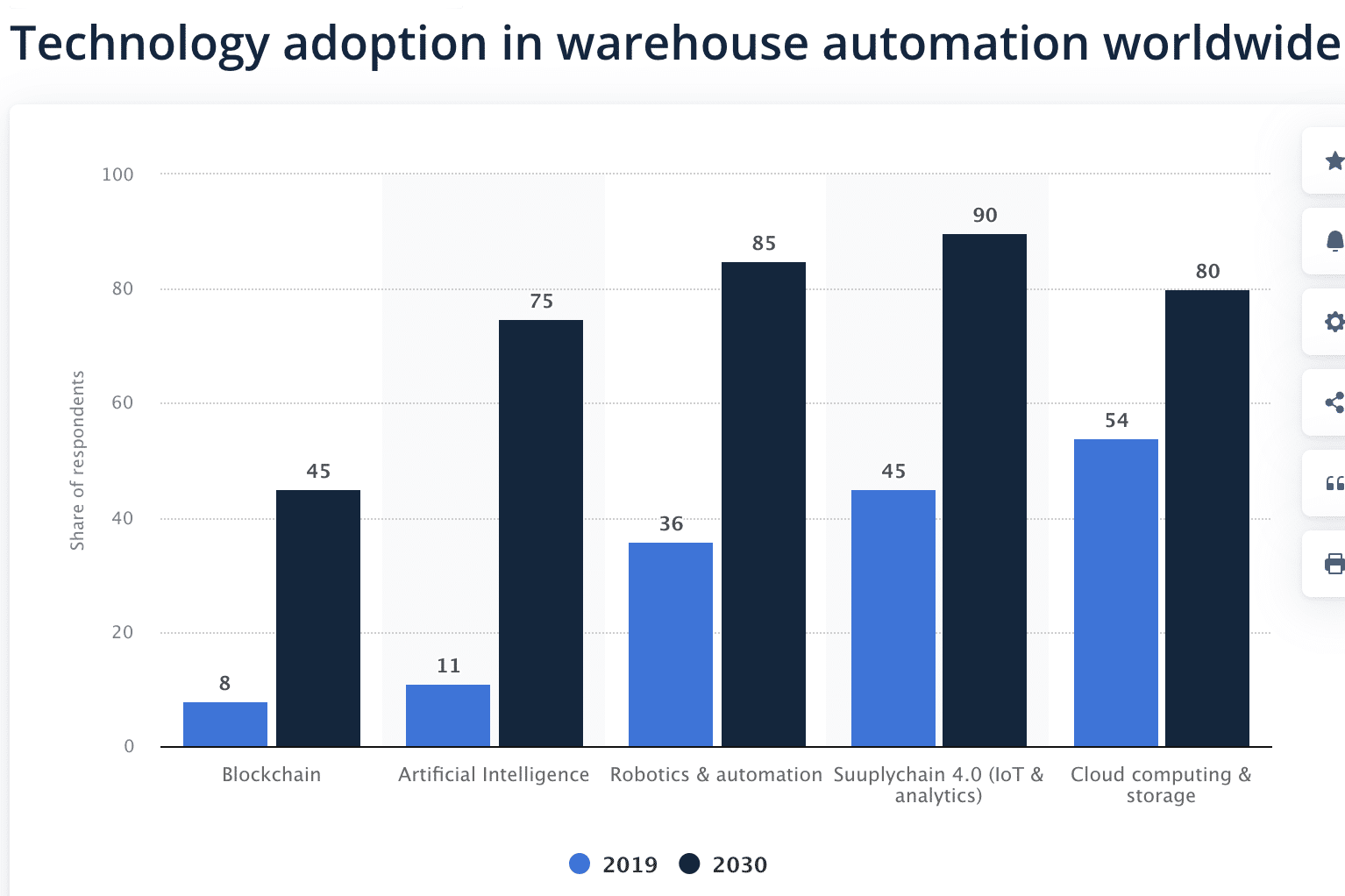

In 2019, adoption for certain technologies in warehouses was sitting just at 8%. However, this number is already steadily increasing thanks to new technologies like AI, IoT, blockchain, and others, and is expected to jump to up to 90% by 2030 for certain systems. Let’s take a closer look at how digitalization can drive improvement across various facets of warehouse management.

1. Efficiency and Productivity Gains

Warehouse digitalization can significantly boost efficiency and productivity in a few key ways:

- Adopting digital tools helps optimize inventory management by ensuring optimal stock levels and decreasing the chances for shortage or excess scenarios with real-time data

- With digitalization, warehouses can improve order accuracy and speed through automated picking systems and robotics, leading to higher customer satisfaction

- By reducing the reliance on manual labor, human error is also reduced, cutting costs related to corrections, returns, or cancellations

- Tools like IoT devices offer real-time visibility into operations, empowering teams to issue immediate adjustments, make important decisions on the spot, and ensure timely deliveries

2. Space Optimization and Resource Utilization

There are several ways warehouse digitalization enhances space and resource optimization strategies:

- Tools can be used to implement smart layouts to maximize storage capacity, such as utilizing vertical space and improving accessibility

- Dynamic slotting and allocation can help ensure products get stored in the most optimal location based on turnover rates and demand

- Digitalization technologies help teams minimize waste and overstock by equipping warehouse teams with real-time inventory data

- Digital tools are more capable of adapting to seasonal and demand fluctuation more seamlessly than traditional ones, allowing for efficient resource reallocation

3. Enhanced Safety and Compliance

There are a few specific ways that warehouse digitalization can improve safety and compliance:

- Automated equipment can help prevent accidents since employees are working less on manual tasks, making the workplace safer for everyone

- Modern tools offer companies a way to store better digital records so that they can ensure regulatory compliance and conduct audits and reports more efficiently

- Real-time data taken from digital technologies allows companies to be more proactive in maintenance and risk management by preventing equipment failure and disruptions

- Comprehensive training programs related to using digital tools help ensure that the workforce is constantly upskilling and participating in an educational program

4. Improved Customer Experience and Satisfaction

Warehouse digitalization can greatly increase customer satisfaction and improve the customer experience. Here’s how:

- Automation and real-time tracking allow for faster order processing and delivery times, so customers receive their orders more promptly

- Digital systems allow for more personalization and customization, enhancing the customer experience by meeting individualized preferences

- Instant updates on order status improve communication and transparency, building more trust and reliability in your brand

- Efficient digital systems streamline returns and reverse logistics, making these processes hassle-free for customers

Warehouse Digitialization Success Stories

Warehouse digitalization is helping companies of all sizes improve their workflows and offer better customer experiences. For multinational companies that span many locations, warehouse digitalization is critical for overseeing warehouse, inventory, and integrating supply chain technologies in different locations. Here’s how two large companies, Inditex and Unilever, improved processes with warehouse digitalization.

Inditex

Inditex, a Spanish multinational clothing company that owns brands like Zara, Bershka, Massimo Dutti, and others, has adopted new digital technologies to remain innovative in its field. With an advanced inventory management system, the company can fulfill orders from both warehouses and store locations, resulting in an integrated system that gets customers their orders quicker. Additionally, by relying on IoT devices like Radio Frequency Identification (RFID), Inditex can easily manage inventory across its global digital supply chain, so that associates in stores of all its brands can locate items anywhere.

Unilever

As a global manufacturer that produces a range of different items including food, beauty, and cleaning products. With more than 30 different brands under its belt as well as 280 factories and 500 warehouses, managing its supply chain requires the use of advanced technologies. Unilever has implemented key technologies like AI tools, machine learning (ML), blockchain, and others to strategically manage its supply chain digitally. For example, Unilever uses ML to gather data for essential business decisions, such as identifying the lowest-performing SKUs that should be removed from product offerings.

aiOla: Powering the Warehouse of the Future

aiOla’s speech AI technology is helping warehouse teams power automations, collect mission-critical data, and move the needle forward on digitalization. Powered by speech alone, aiOla is capable of triggering actions to replace manual operations and gather otherwise lost data that can be used for strategic decision-making.

aiOla’s speech AI can understand over 100 languages including different accents, dialects, and industry jargon. It is also highly accurate in any acoustic environment, making it a reliable tool on any noisy factory or warehouse floor. Thanks to aiOla, warehouse teams have been able to work more efficiently:

- Warehouses using aiOla increase the number of pallets processed hourly by 25%

- Teams saw a 60% reduction in incident resolution time

- On average, there was a reduction of 4 safety incidents per shift

aiOla empowers warehouse teams to work smarter, quicker, and safer all through the power of speech, meaning there’s little to no learning curve and no steep onboarding timeline. With aiOla, warehouses can collect more reliable data to inform workflows, improve the customer experience, predict machinery maintenance needs, and reduce costs.

Warehouse Digitalization: Powering the Warehouse of the Future

Looking ahead, it’s impossible to imagine a scenario where warehouses still rely on traditional workflows and manual operations. As consumer demands for quick delivery, tailored experiences, and customized care grow, warehouses need to adapt to the market demand and adopt cutting-edge technologies. With a speech AI system like aiOla, you can ensure your business is future-proofed, flexible, and can scale with your organization’s evolving needs.

Book a demo today to see how aiOla can be a core part of your warehouse digitalization strategy.