The vision of a fully autonomous manufacturing floor has always been an exciting prospect, but with the addition of emerging artificial intelligence (AI) technologies to the industry, it’s no longer a fantasy. The future of AI in manufacturing is promising, offering the industry ways to evolve and improve productivity, cut costs, and ensure more sustainable operations.

Still, as AI becomes increasingly integral to manufacturing, new concerns arise, including ethical implications and how it will fit in with the new concept of Industry 5.0.

This blog post will look at how AI is currently used in manufacturing, our predictions for future trends in the field, how companies can address ethical considerations, and why technologies like aiOla are leading the way in industry change.

Current and Emerging AI Technologies in Manufacturing

The future of AI in manufacturing is promising, but for all intents and purposes, it’s already here. Manufacturers are already implementing advanced AI technologies in their manufacturing operations, completely transforming their traditional operations into more modern ones. Before we look at the direction in which AI is moving in the manufacturing sector, let’s examine its current applications in the industry today.

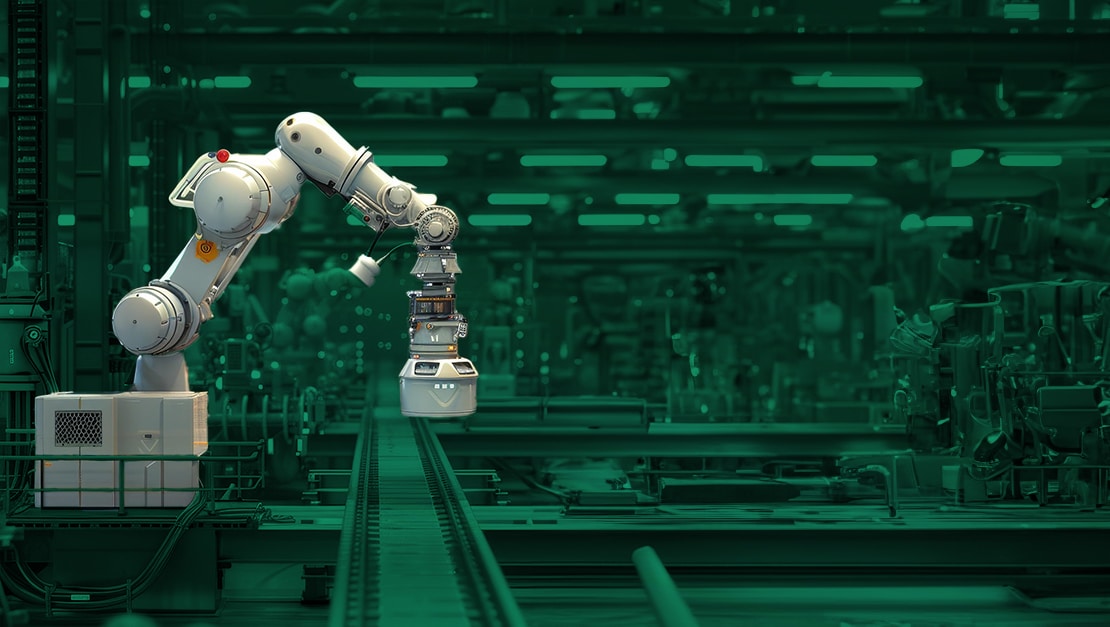

- Robotics and automation: AI is used to power robots and automation systems, which are used to improve manufacturing speech, precision, and efficiency. AI-powered robotics systems can handle complex tasks and reduce errors related to human oversight, increasing production and quality levels

- Internet of Things (IoT): IoT devices are turning manufacturing plants into smart factories by connecting different devices for enhanced analysis and real-time data collection. This helps manufacturers with predictive maintenance and data-driven decision-making

- Predictive analytics: AI-driven predictive analytics technologies can leverage data from IoT devices to predict equipment failures or maintenance needs. This helps companies stay proactive and avoid downtime, costly repairs, and extends machinery lifespan

- Digital twins: Generative AI technology and deep-learning neural networks are used to create digital twins of physical assets, like production lines, enabling manufacturers to simulate and optimize new processes to reduce waste and facilitate better design

- Augmented and virtual reality (AR and VR): AR and VR technologies can make training more engaging and “hands-on” and help simulate maintenance needs and design processes. This allows manufacturers to better test different production environments while fostering a safer working environment

AI’s Role in Transforming Manufacturing Processes

As AI platforms continue to advance and allow for new capabilities in manufacturing, we’re seeing the way manufacturers operate shift. From making operations more productive to enhancing forecasting abilities, AI is on track to make manufacturing more reliable, efficient, and cost-effective. Here are a few key ways AI is influencing the future of manufacturing

Production Optimization Through Predictive Analytics

Through leveraging AI to gather, screen, and analyze data including historical patterns and trends, teams can work 10 to 20 percent more efficiently. AI technology can help improve efficiency by predicting events like machinery malfunctions and maintenance needs as well as busier periods. This allows businesses to remain one step ahead and plan production and work schedules accordingly, reducing bottlenecks and downtime to improve throughput.

Adaptive Systems for Dynamic Production Environments

AI makes it easier for manufacturing systems to remain flexible and adaptive to ongoing changes in production requirements. When connected to AI technologies, these systems can use machine learning (ML) algorithms to shift operations based on current demands, availability of materials, and workforce, ensuring procedures are adaptable.

Quality Control and Defect Detection

By employing computer vision and ML, companies can enhance their existing quality control practices to assist in finding defects and inconsistencies better than the human eye alone. While small issues can be missed by inspectors, AI technology can ensure higher quality assurance standards on a production line to help reduce wasted products and resources.

Supply Chain Optimization and Demand Forecasting

With AI, companies can improve their supply chain transparency and efficiency. AI has the power to deliver predictive demand forecasting to better manage inventory levels, rendering all levels of a supply chain more effective. ML models can analyze trends and historical data to better forecast demand, empowering manufacturers to maintain optimal inventory levels.

Outlook and Predictions on the Future of AI in Manufacturing

In 2023, the global AI manufacturing market had an estimated value of USD 3.2 billion, and thanks to the industry’s increased desire for workflow automation, lower costs, and increased efficiency, that number is anticipated to grow to over 20 billion by 2028. Looking at the future of AI in manufacturing, it’s clear to see why the industry is expected to grow at a CAGR of over 45%. Here’s a look at some of the most promising future trends of AI in manufacturing.

Generative AI and Manufacturing

Generative AI technology gives manufacturers the ability to create new designs and content based on provided parameters, allowing for more options to be considered. For example, General Motors is using generative AI to optimize vehicle parts and create parts that weigh less. In the future, we expect to see generative AI playing a larger role in manufacturing to help companies create multiple models to improve both production processes and the final products.

Improving Sustainability in Manufacturing With AI

AI is posed to make a significant difference in how sustainable modern manufacturing practices can be. Let’s look at the food industry for example. As AI technology becomes stronger and more accurate, it will be relied upon more frequently for quality control. Errors in quality control and product recalls can cost companies upwards of USD 10 million, and lead to wasted materials. One UK-based study showed that human errors on a production line led to 10.2 million tons of food waste, which could be avoided with the adoption of cutting-edge AI software for quality control.

Factory Layout Optimization

AI can be used for more than just manufacturing operations themselves, but other processes such as factory planning. AI can take into consideration multiple factors, such as operator safety, process efficiency, and changes in production to influence the layout of a facility. Furthermore, as companies need to remain agile, AI can help reconfigure spaces for short-term projects or evolving processes. When combined with IoT sensor data, this technology can further optimize factory layouts for heightened performance and safety.

Integration with Emerging Technologies

The convergence of AI with other emerging technologies such as 5G, edge computing, and quantum computing is likely to unlock new possibilities in manufacturing. These eventual discoveries will enhance data processing capabilities and supply more complex operations. For example, companies are already using web3 technologies like blockchain and smart contracts to enhance manufacturing logistics and supply chain processes. These emerging technologies can help manufacturers track goods in real-time to help improve delivery times, clear customs, reduce reliance on manual paperwork, and reduce the risk of lost or stolen items.

Industry 5.0 and Ethical Considerations in the Future of AI in Manufacturing

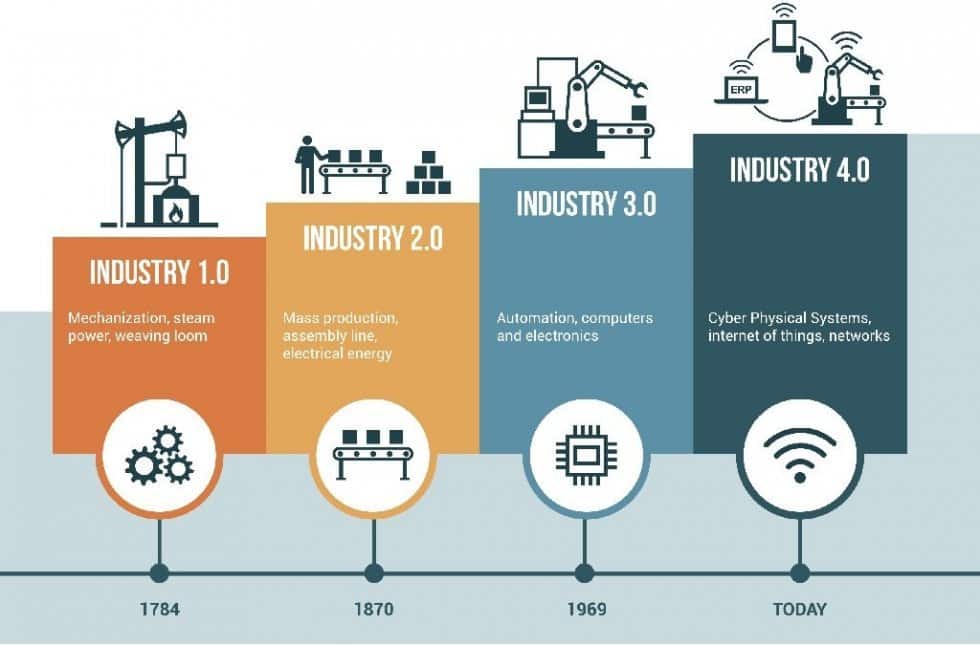

As new technologies change the way we work, the entire manufacturing field is at the beginning stages of shifting its focus from Industry 4.0 to Industry 5.0. With Industry 4.0, there was a focus on automation approaches to enhance the way we work, however, the aims of Industry 5.0 go a step beyond work approaches and adopt a more human-centric practice.

Industry 5.0 extends further than workplace efficiency and productivity and applies a shift in focus toward both social and economic value, putting more emphasis on human well-being. As the adoption of emerging AI technologies in the future of manufacturing may potentially put jobs at risk, this creates ethical implications for industry leaders to address, such as:

- Data privacy and security: It’s critical to protect sensitive data used in AI systems by implementing robust security measures to protect against breaches or unauthorized use

- Job displacement: As AI enhances productivity, it also raises concerns about job displacement, and it’s essential to build workforce transition strategies to upskill and reskill workers

- Accountability and governance: It’s important to establish accountability for AI systems by implementing governance frameworks for AI deployment, ensuring it aligns with legal requirements and ethical standards

- Bias and fairness: AI algorithms need to be continuously trained to avoid biases that may lead to the unfair treatment of workers and reflect a diverse workforce

Looking to the Future of AI in Manufacturing with aiOla

As a cutting-edge speech AI technology, aiOla is leading the way in changing how manufacturers operate. Relying solely on the power of speech, organizations can use aiOla to garner spoken data that’s otherwise lost and trigger actions and automations in seconds.

aiOla can understand over 100 languages in any accent, dialect, or industry jargon and can operate in any acoustic environment, making it ideal for factory floors. With aiOla’s speech AI, manufacturers can boost productivity by:

- Gaining real-time insights into processes for better decision-making

- Ensure hands-free operation so employees can keep their eyes on their tasks and work more safely

- Decrease time spent on inspections by eliminating the need for manual entry or paperwork

- Send immediate alerts and notifications to employees and management for stronger collaboration

- Improve predictive maintenance needs to reduce downtime or production disruptions

With aiOla, manufacturers have seen a 30% increase in production uptime as well as a 90% decrease in manual operations. When looking towards the future of AI in manufacturing, aiOla is one tool that can help companies enhance the capabilities of their existing workforce with smart technology.

The Future of AI in Manufacturing is Now

As modern technology and AI evolve at breakneck speed, there’s no denying that the industry will go through further significant changes in a short time period. As we witness this evolution, it’s important to keep ethical considerations front and center to ensure a sustainable transition to a new type of manufacturing.

aiOla’s speech AI technology helps companies strengthen the skills of their existing workforce and supports it through tools that can automate manual work and make operations safer and more efficient for everyone on a factory floor.

Book a demo with one of our experts to see how aiOla can transform your manufacturing operations.