A first article inspection (FAI) report is a document in the manufacturing industry that helps in verifying a product’s compliance with specific requirements before full-scale production. First article inspection reports (or FAIR, for short), are most often used in manufacturing industries for products related to aerospace, defense, automotive, and medicine. By conducting a FAI, a company can ensure that its new product meets necessary standards and rectify potential issues before main production. In this article, we’ll take a closer look at FAIRs, their components, how to create your own, and how AI tools and software can improve the process.

When Do You Conduct a First Article Inspection Report?

An FAIR requires inspections, sometimes by an external company or player. These inspections are usually carried out in scenarios such as:

What is the first article inspection in AS9100?

- A product is being produced for the first time

- A product’s design is changing

- There’s been a two-year pause in production and it’s resuming or the process changes

- The manufacturing location changes

You can do a full or partial FAI depending on your production circumstances. For example, a full FAI is needed for new parts or facilities, but you can do a partial FAI when there are changes to a part’s design or the production process.

First Article Inspection Report Requirements: What’s Included in the Report?

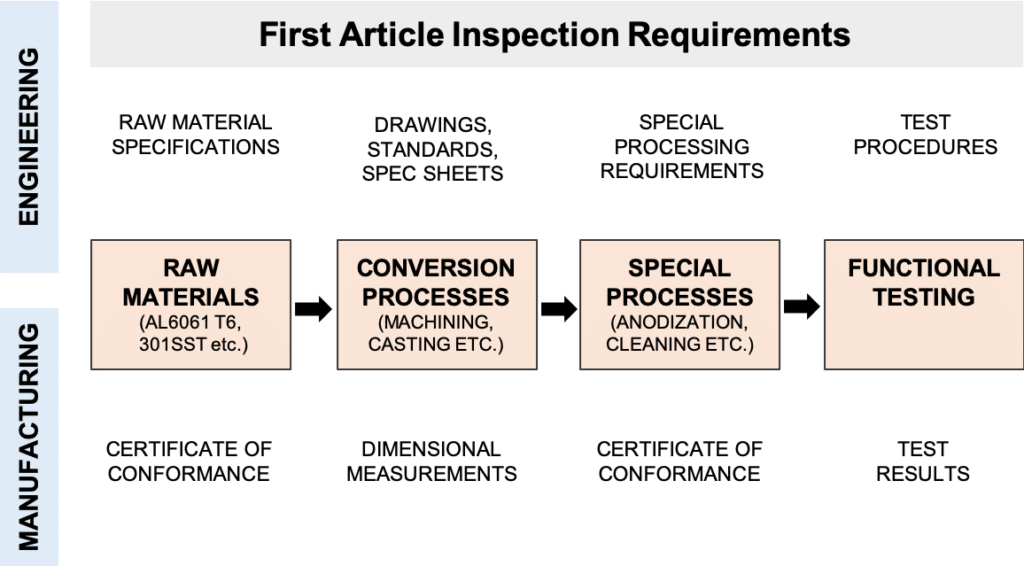

Source: 1factory

Depending on the industry you’re in, there may be different elements to a FAIR. A FAIR comprises different reports with various required and conditional fields that need to be filled out to complete a round of reporting. Regardless, completing the report is always a thorough process that requires diligence and patience. For example, the aerospace industry uses the AS9102 First Article Inspection Report format, which has three parts:

- Part Number Accountability Form: Checks the part name, number, and revision level to ensure it’s the correct part and traceable throughout FAI and production

- Product Accountability Form: Looks at materials, processes, and product specifications or tests that are noted as design requirements

- Characteristic Accountability form: Provides a summary of each part’s design characteristics such as dimensions, tolerances, measurements, and more

- Balloon Drawings: These drawings are part of the third report and support it by guaranteeing each design characteristic meets the requirements

Why Are First Article Inspection Reports Important?

The production of parts for industries like aerospace, medicine, or defense requires deep precision and accuracy. Manufacturing parts for these industries is demanding, and vendors need to be able to meet highly specific requirements for a part to be suitable, such as a part of an aircraft.

Without a system like FAI in place, manufacturers may end up creating multiple parts that aren’t suitable when issues could have been prevented in the first production run. This wastes time and resources and can erode trust between a supplier and customer.

First article inspection reports are an element of quality control that allows companies to detect errors early on to avoid losses. It also reassures a customer that their products are made precisely to their standards. That said, FAI isn’t treated as the final step in quality control, but rather the first, with other steps supporting production as it progresses.

Steps to Complete a First Article Inspection Report

Before setting pen to paper on your report, consider the different steps you may need for your FAI. These steps can differ depending on your industry or company’s specific needs, but it’s a good idea to evaluate each one before beginning to save time.

Step 1: Determine the FAI you need

Consider whether you need a full or partial first article inspection based on whether you’re producing a new part or making changes to production processes.

Step 2: Gather the right documentation

Each business will have specific documentation they’ll need, but having them all together and accessible will make completing the inspection and report easier. Some forms you may need include:

- Bill or materials

- Engineering drawings

- Digital product data

- Source information

- Manufacturing work order

- Balloon drawings

- The three AS9102 FAIR forms

Step 3: Build your inspection plan

In this step, start by identifying the parts to be inspected and prepare your AS9102 forms accordingly. Make sure you have all the documents needed available based on the data you’ll need in the forms and prepare your manufacturing process accordingly.

Step 4: First production run

Manufacture the part using your plans, making sure to document the process along the way for the report.

Step 5: Collect data and a sample

According to your inspection plan, begin to inspect a sample manufactured part, ideally one selected at random. Record the data as you find it.

Step 6: Create your first article inspection report

Based on the sample and data, start recording results from the first manufacturing run and filling out the necessary FAIR forms before submitting them for approval from relevant stakeholders.

First Article Inspection Software and AI Tools

Some companies complete FAIRs with pen and paper, but considering this is such a sensitive and involved process requiring a high level of precision, this can lead to errors. Additionally, balloon and other drawings can be time-consuming to produce. FAIR software helps companies meet specific requirements and provides first article inspection report templates, helping them keep track of inspection and form processes and balloon drawings progress.

When it comes to artificial intelligence (AI) tools, this technology can complement first article inspection software by providing companies with a more complete image of data, patterns, and insights that can be applied to reports. Let’s take a closer look at a specific example by examining how speech AI, like aiOla, can assist in FAIR.

Integrating aiOla’s Speech AI Solutions in FAI reports

aiOla is a speech AI technology that enables companies to harness the power of voice and turn it into automation and data. With aiOla, all employees need to do is speak as usual, and using advanced technologies like natural language understanding and automatic speech recognition, the AI can help complete tasks, collect data, and automate workflows.

When it comes to completing FAIRs, it’s important to be as accurate as possible and ensure you have a full picture, which often means a lot of details and data. When you use speech AI, this data can be recorded when you’re naturally speaking, helping you gather the information you need to complete your reports.

With aiOla, you get many of the benefits of first article inspection software without adding additional time and resources to complete reports.

aiOla allows you to:

- Collect data at the source during the first run production entirely through speech

- Remain hands-free throughout the entire process for quicker inspections

- Gain meaningful insights from data gathered through speech, which can add further details and layers to FAIRs

- More accurately collect data and real-time feedback for better compliance

With speech data, you’re capturing an otherwise lost form of information that can be used to enhance reporting and quality assurance. aiOla has led users to decrease inspection time by 45%, and when doing multiple rounds of FAIs, this can lead to much higher productivity and more time efficiency.

Leveraging AI Tools for First Article Inspection Reports

As AI becomes a more mainstream a tool in our daily workflows, it’s natural for it to take a bigger role in assisting FAIRs. First article inspections will always require thorough human involvement to assess, monitor, and review production processes and results to fill out reports, but AI like aiOla can make this entire process quicker, more accurate, and more efficient. Through the use of speech AI for first article inspections, you can expect fewer errors, less wasted time and resources, and better results.

Book a demo with one of our experts to see how aiOla can help you complete first article inspection reports.