Supply Chain Technology: Trends, Features, and Functions

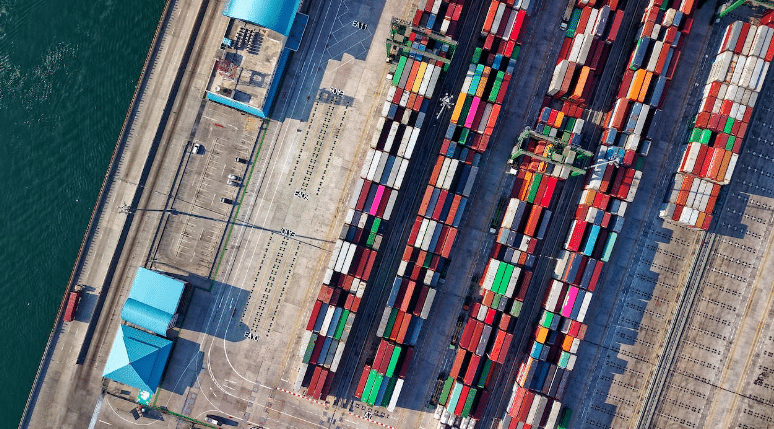

A supply chain is a lot like dominoes- if one piece falls, the entire setup thereafter crumbles. Supporting supply chain efficiency, organization, and fluidity is critical to reduce costs, deliver goods on time, and satisfy customers and employees alike. That’s where supply chain technology comes into view. And, new supply chain solutions seems to be evolving daily.

We’re going to define supply chain and logistics technology, look at supply chain technology trends, and answer, “What is a technical supply chain?” so that you have all the knowledge you need to increase your operational efficiency.

What is Supply Chain Technology?

Supply chain technology is digital equipment that is used to support a business’ efficiency and organization of its supply chain. At the heart of supply chain tech sits a large volume of data that is used to make improvements and forecast for the future.

The most elementary type of technology for supply chains allows its users to input their own data and send vital messages. On the other end of the spectrum, supply chain technology can include artificial intelligence (AI) and robotics to automate processes.

Why Does Supply Chain Technology Matter?

There are a lot of moving parts when it comes to dealing with your supply chain- from goods to people involved. As such, supply chain tools can streamline your organizational processes and help to maintain order.

Here’s a look at the key concepts of what makes supply technology function:

Digital Transformation in Supply Chain

Supply chain digital transformation happens when you align your processes and data into a centralized platform. With the assistance of technologies like machine learning, AI, and the internet of things (IoT), you can collect data, organize it, and analyze it to predict and even avoid issues in the future.

Role of Data

As mentioned, supply chain technology runs on data. Data enables visibility and allows organizations to make informed decisions. With historical data, businesses can apply predictive analytics to predict the future, including demand, potential supply chain disruptions, and even how customers may behave. All of this information makes it possible for businesses to make decisions today on what is likely to happen tomorrow.

Behind the Scenes: The Varied Components of Supply Chain Technology

Supply chain software, depending on its sophistication and features, is powered by different technologies.

Answering, “What is the latest supply chain technology?” makes it easier to understand the role of supply chain technology across industries. These are some of the most critical technology operating within the platforms and software you choose to use when implementing:

Internet of Things (IoT) in Supply Chain

The Internet of Things (IoT), despite its somewhat funny name, is highly powerful. IoT refers to the network of devices (a.k.a. Physical and tangible “things”) that make data exchange and connection work. For example, these “things” have sensors, software, and technology that are capable of sharing information, without the need for human intervention. With real-time data collection made possible, the IoT ecosystem is applicable within supply chains. For example, it can be used for: asset tracking, predictive maintenance, inventory management, temperature monitoring, route optimization, and more!

Artificial Intelligence (AI) and Machine Learning (ML)

Before all this technology, supply chain management (SCM) was based on algorithms and optimization techniques. With the inclusion of machine learning and artificial intelligence, the uses in supply chain management are seemingly infinite. AI and ML help to provide: autocorrection in the supply chain, reinforced learning (for decision-making in changing environments), product segmentation (through clustering algorithms), demand planning, digital twins, and truckload generation, to name a few.

Blockchain in Supply Chain

When you hear “blockchain,” you likely immediately think of digital currencies. But, blockchain has a wide range of applications, including supply chain management. Supply chains are technically a network of companies that are connected through the movement of goods. With each “link,” a new business is adding value to the chain. To continue moving forward, each step occurs through a transaction- either of goods, information, or finances. Blockchain, an immutable ledger, can be used to record these transactions securely with a single source of truth.

Cloud Computing and Supply Chain Management

Last but not least, cloud supply chain management works by way of cloud computing, as opposed to on-premise equipment. With global supply chains, this is more important than ever as cloud computing makes data accessible from anywhere and grants cloud backups, which can help to protect against theft or data loss.

Benefits of Supply Chain Technology

Given all of these advancements in technology, your supply chain will of course be positively affected and optimized. With supply chain technology in a business, you can expect to gain multiple advantages, including:

- Efficiency and Cost Reduction

- Enhanced Visibility and Transparency

- Improved Collaboration and Communication

- Risk Mitigation and Resilience

- Better supply chain planning

- Reduced costs for maintenance, operations, and repair of supply chain equipment

- Faster shipping and delivery times

- Improved supply chain integration with customers and suppliers

- Higher profitability

Challenges in Adopting Supply Chain Software

When adding supply chain technology within your organization, it’s possible you’ll be met with some hurdles, as any change has its own fair share of uphill battles. Knowing in advance what these challenges may be can help you plan and prepare to overcome them.

Take a look:

Implementation Barriers

You may run into implementation barriers due to the fact of human nature, which supposes that most people are averse to change. Culture and people tend to dominate as the greatest implementation barriers, so, it’s best to spread awareness of supply chain technology and promote buy-in before implementation begins.

Data Security and Privacy Concerns

Data is paramount for supply chains, as is its security and protection. Not only must data be properly integrated, but it must be stored and protected through its transfer at every turn.

Skill Gaps and Training Needs

Depending on the type of technology you wish to use, you may need to spend time training your team on how to use it. This requires time, money, and a plan. Keep in mind, there are certain supply chain technologies that can be used with little to no learning curve. Take aiOla as an example. aiOla is a speech-driven AI tool that digitally transforms your existing processes and enables your team to execute the process through speech. Most importantly, aiOla understands business-specific jargon, in any language, acoustic environment, and accent.

Industry Applications

Supply chain technology is applicable in any industry that manages a supply chain (so basically, all). As an abbreviated list, check out how supply chain systems can impact each of these sectors:

- Retail and E-commerce: real-time asset tracking, digital twins, fleet tracking, etc.

- Manufacturing: additive manufacturing, warehouse robotics, equipment inspections, distribution and packaging optimization, quality control

- Logistics and Transportation: automation, robotics, inventory management, real-time tracking, visibility

- Healthcare: advanced data analytics, ethical sourcing and inventory management, care expansion, procurement, quality control, information management

- Agriculture: traceability, disease outbreak management, real-time transit tracking

Wrapping Up

Supply chain technology trends expand and innovate nonstop as supply chain technology continues to add value to businesses across industries. From speech AI, such as aiOla, to machine learning and blockchain (and everything in between), supply chain technology contributes to increased visibility, enhanced efficiency, and improved satisfaction for everyone involved.