According to the MHI Annual Industry Report, the majority of supply chain leaders (74%) are increasing their investments in technology. Warehouse automation and Ai in warehousing are at the top of the list of priorities because of the many benefits that come along with its implementation, especially for employees.

In this article, we’re going to explore the rise of AI in warehousing, what it means for employees specifically, and how employers can best prepare to make the most out of these innovations.

The Rise of AI in Warehousing

For every supply chain, warehouses are considered to be the lifeblood, designed to store, sort, and distribute goods. With AI in warehousing growing in popularity, its use cases almost seem to be limitless.

AI in warehousing can assist with:

- Automated order fulfillment

- Robotics

- Real-time inventory management

- Equipment maintenance

- Back-office operations

- Occupational health and safety

- Planning

- And more

Enhancing Employee Efficiency and Productivity

As AI in warehousing shines across these endless scenarios, there’s one group of people that end up really feeling the upsides– employees. If warehouses are the lifeblood of logistics, then employees can be considered the arteries and veins, keeping the system running healthily.

Employees have to handle many tasks, some of which are often considered to be dangerous with heavy loads and machinery. With the use of AI in warehousing, employees are able to:

Automate Routine Tasks

Autonomous mobile robots can handle repetitive tasks like picking, packing, and sorting. Rather than relying on humans to scour corridors and aisles for products, the robots can do the tedious labor. There are also palletizer robots to position the goods on pallets, conveyor systems to transfer items to different areas, and sorting robots that utilize computer vision to boost efficiency, to name a few.

The intention behind the use of robotics in warehousing is not to replace human resources. Instead, it enables humans to focus on responsibilities that require strategic thinking and problem-solving, all the while, the AI-powered robots can handle the strenuous effort and redundant taskwork.

Manage Inventory

One of the most important aspects of supply chain management and warehousing is inventory management. Holding onto too much inventory becomes a costly liability, whereas having too little inventory can result in lost revenue. AI systems can be used for real-time inventory tracking, so that you can always trust you’ll have exactly what you need on hand when you need it. Not only does this better satisfy consumer demand (with the additional benefit of AI analytics for proper demand forecasting), but it also reduces manual stock checks and errors. Manual stock checks are time-consuming, error-prone, and often one of the last things that any employee wants to be spending their time doing.

Improve Safety and Reduce Physical Strain

Perhaps one of the most touted upsides of AI in warehousing comes along with its safety advantages. If you work or manage a warehouse, then you know all too well the number of hazards and threats that exist in these ever changing environments.

One type of robotics called exoskeletons, which are wearable devices to assist with posture and motion, help to protect human bodies during their physical activity. They lower fatigue and reduce strain on one’s muscles, back, and shoulders, thereby reducing incidences of injury.

Similarly, AI-powered robots are also able to design safer warehouse environments by calculating the most efficient routes and minimizing obstacles.

Last but not least, AI tools can leverage predictive maintenance, which predicts equipment fails even before they occur. By doing so, warehouse managers and owners are able to reduce downtime and prevent potential hazards.

Optimize Training and Skill Development

Regardless of how seasoned your warehouse team is, there’s always room for improvement. That’s why it’s of great value to provide consistent training and development opportunities.

With AI, it’s easy to personalize training programs based on an individual’s needs. Additionally, with solutions like virtual reality (VR) and augmented reality (AR), training environments can be set up anywhere, creating immersive training experiences without the hazardous risks involved.

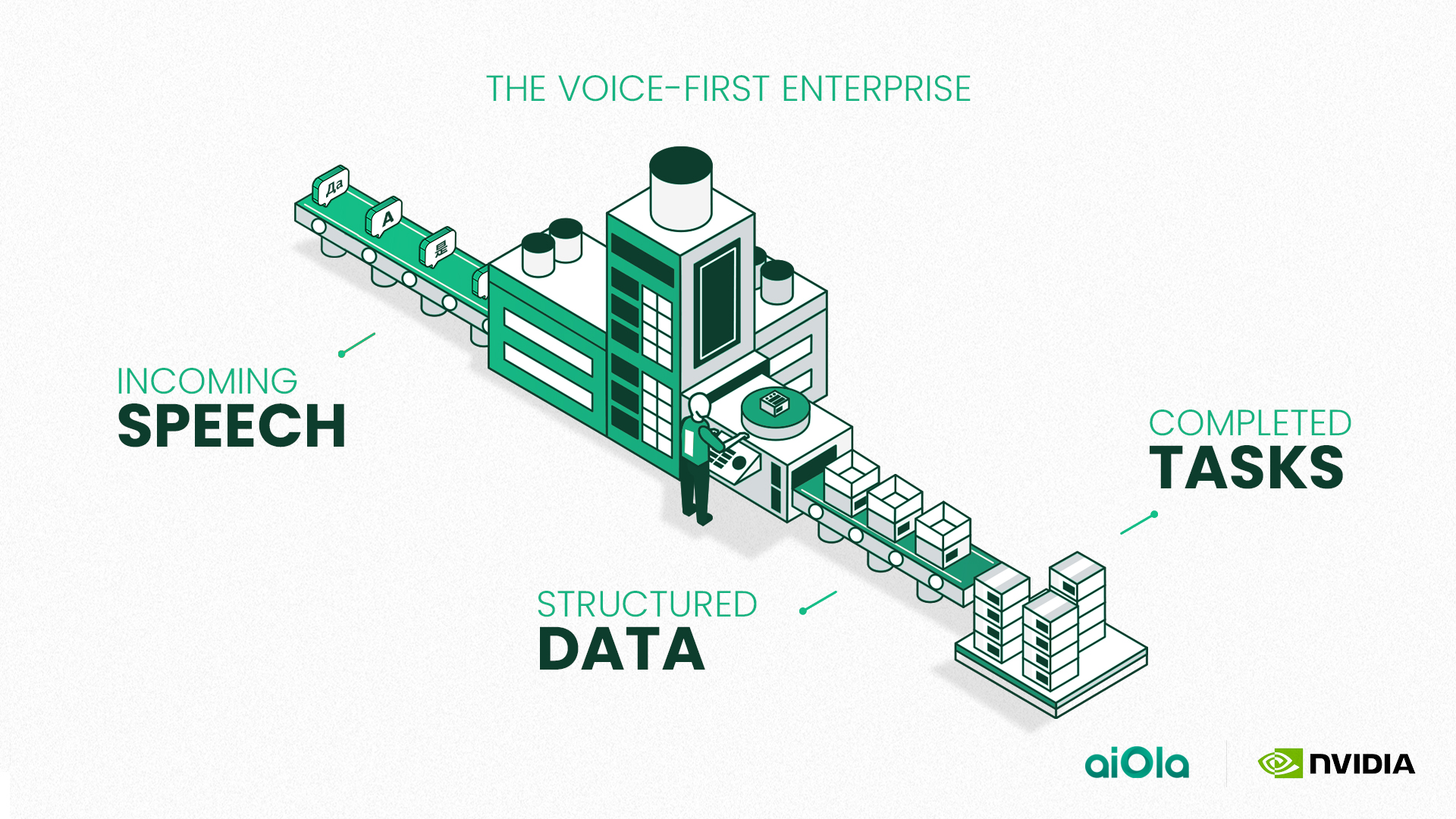

Enhance Communication with Speech AI

Another form of AI that is sweeping across warehouses is the use of speech AI, or voice-activated systems. Speech AI, like aiOla, enables hands-free or touch-based operations, ideal for employees who are working in noisy warehouse environments.

In aiOla’s unique case, its speech recognition software can understand business-specific jargon, in any accent, language, and acoustic environment. With a voice-activated system, frontline warehouse workers can leverage AI for efficient documentation, data capture, communication, and collaboration in real-time.

Employees can talk through workflows and checklists, all the while, keeping their heads up and hands on the machinery. When another team member is required to address an issue, the system will automatically route the necessary information to the relevant stakeholder to take action. Essentially, words are transformed into immediate action, enabling greater efficiency, safety, and collaboration.

Not only does speech AI benefit employees, but the upsides trickle down to customers, too. Speech AI enables team members to handle customer queries and support requests more quickly, leading to greater customer satisfaction.

Addressing Employee Concerns

Deploying AI in warehousing has to be done with care and consideration. The introduction of any new technology creates the possibility of pushback and fear, so it’s best if management teams and owners know what to expect before getting started.

For example, employees may be worried about:

- Job Displacement: First and foremost, employees may believe that AI in warehousing is there to replace their jobs. It’s up to leaders to communicate that AI in warehousing is here to augment capabilities, rather than make human resources obsolete. Showcase the various ways in which AI can actually help to make their jobs easier and less strenuous.

- Role Changes: Another way to position AI is to explain that their roles are going to evolve, not disappear. AI can replace the need for employees to conduct manual and repetitive tasks, data entry, and physically-trying responsibilities.

Tips for Employee Acceptance and Adaptation

In order to position employees to desire the advantages of AI in warehousing, it’s optimal if they can be involved in the entire adoption process. Bring them in during the planning phase. Listen to their feedback of pain points and explanation of processes that are likely ripe for innovation. This way, when AI serves as the solution, they feel like they were part of the decision.

Future Trends and Developments

Technology innovates exponentially. From wearable technology to automated guided vehicles (AGVs) to voice recognition, and more. AI in warehousing will continue to shape how warehouses operate.

In terms of employees, AI will continue to enable supply chain leaders to make informed, data-driven decisions, implement process improvement, and optimize operations to avoid waste. For frontline employees, their workforce will be safer, more collaborative, and less physically draining.

Closing Thoughts

AI in warehousing (and all industries, for that matter), is prompting businesses to operate with efficiency and reduce waste. Once business leaders can get over the hurdle of any pushback, integration and deployment tends to be seamless, with nearly immediate ROI.

If you’re looking for how to prioritize your employees’ health, safety, and peace of mind, then the answer lies in AI. It’s your turn to take the first step forward.